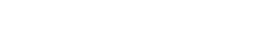

Recently, certified by Institut für Solarenergieforschung in Hameln (ISFH), the HJT solar cell developed by Maxwell Technologies reached a conversion efficiency of 25.05%, with its total area of 274.3cm2 (M6 size). This marks a new record in the field of HJT mass production technology.

This HJT solar cell, all produced with high-efficiency HJT production equipment and technology developed independently by Maxwell Technologies. The 25.05% conversion efficiency certification not only reflects the advanced level of research and development of Maxwell Technologies’s laboratory, but also means that, driven by its mass production technology, the achievable yield efficiency of HJT cells has passed the 25% landmark, which is a milestone for promoting the commercial application of HJT solar cells.

The HJT Solar Cell R&D Team and Vacuum Equipment R&D Team of Maxwell Technologies are composed of more than 200 professional R&D technicians, focusing on R&D, design and manufacturing high-capacity and low-cost PECVD, PVD, screen printing and LED light soaking and other core production equipment dedicated to HJT solar cell production, as well as researching and developing advanced manufacturing technology for HJT high-efficiency cells and modules.

In January 2019, the Company's HJT PECVD and its supporting equipment project was launched, since then Maxwell has pioneered the development of the first generation of production capacity of 200MW, the second generation of 400MW of PECVD equipment, and through further independent research and development, Maxwell has become the first Chinese HJT cell production line equipment manufacturer to provide HJT overall manufacturing solutions to the solar industry.

As the “rising star” of the solar industry, the theoretical conversion efficiency of HJT technology is 27.5%, with low degradation rate, excellent temperature coefficient, high bifaciality, good low-light response and other advantages, the power generation gain in HJT module’s life cycle will be significant. Moreover, there’re only four processes including texturing, silicon-based film deposition (PECVD), transparent conductive film deposition (PVD) and screen printing for HJT cell’s manufacturing, and as a platform-based technology, HJT has the potential to overlay other advanced processes to increase conversion efficiency. It is a technology that is in hopes of making low-cost and high efficiency a reality in the solar industry.

As the industry's leading solar cell equipment manufacturer, Maxwell Technologies has always stood firmly on its belief in the importance of independent research and development, and continue to study in the forefront of high-efficiency solar cell production technology. Maxwell Technologies focuses on the whole solar industry, with the customer-centric value, the Company explores HJT solar cell manufacturing process optimization and cost reduction solutions based on the needs of solar cell and module manufacturer clients, and contributes to the sustainable development of the solar industry with its commitment to promoting the HJT technology and its applications.