The 17th SNEC International Photovoltaic Power Generation and Smart Energy Conference & Exhibition was held grandly at the National Exhibition and Convention Center (Shanghai) from June 13-15, 2024. Over 3,000 exhibitors and hundreds of thousands of photovoltaic practitioners gathered to jointly explore the long-term prospects of the photovoltaic industry around specific themes such as "technological innovation, cost reduction and efficiency improvement".

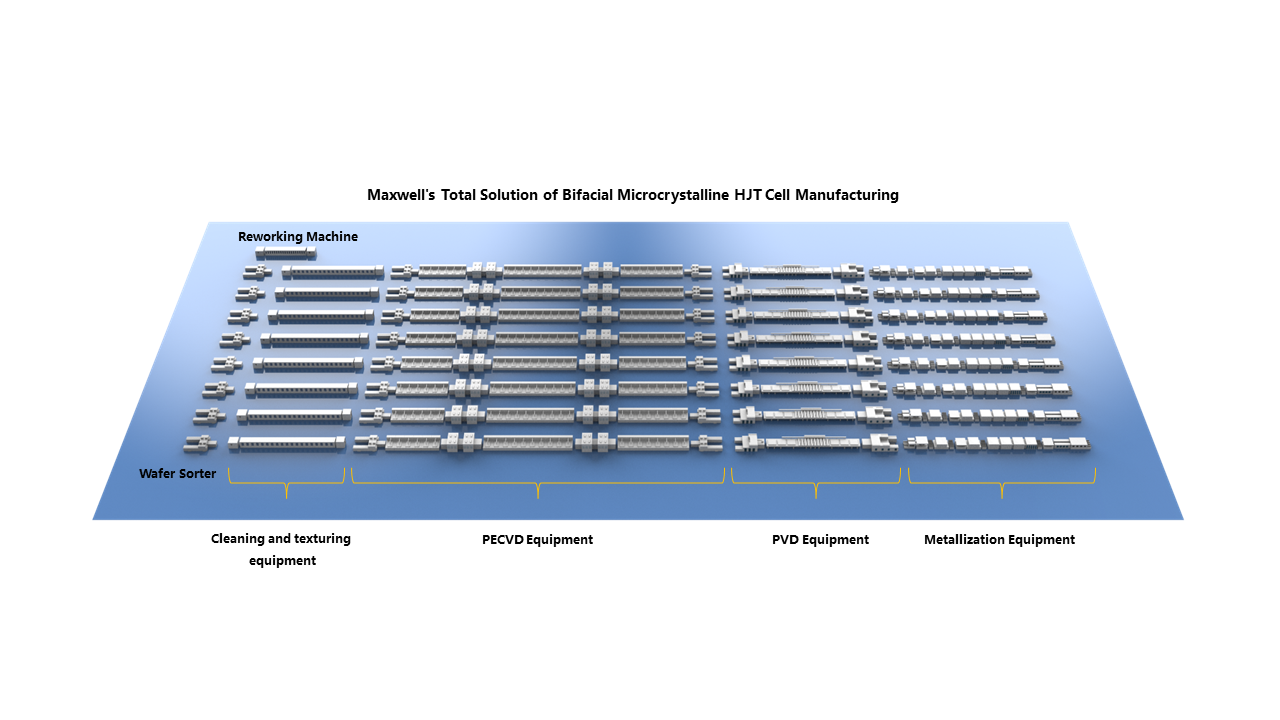

Maxwell showcased its latest product, a high-efficiency cell manufacturing solution based on GW-level bifacial microcrystalline heterojunction (HJT), at booth A560 in Venue NH, attracting enthusiastic attention and exchanges from Chinese and foreign customers as well as various partners.

Achieve Cost Reduction and Efficiency Improvement with HJT

In 2022, Maxwell successfully developed its high-efficiency cell technology based on bifacial microcrystalline HJT and pioneered whole-line mass production equipment, with a single-line annual production capacity of 600MW. Thanks to the company's leading and boosting efforts, the bifacial microcrystalline technology emerged as the mainstream in the field of HJT in 2023, achieving a significant improvement in the conversion efficiency of HJT cells during mass production.

Through further research and innovation, in early 2024, the Company upgraded the annual single-line production capacity of the whole-line high-efficiency cells based on bifacial microcrystalline heterojunction to the GW level. The core PECVD and PVD equipment have their chambers expanded while the original multi-chamber structure design remains, thus maintaining the legacy of layered high-quality coating. This not only ensures the high efficiency and high pass-yield of cells, but also significantly improves the whole-line production capacity and reduces operating costs in various aspects such as unit labor, unit equipment occupation, and unit energy consumption.

Recently, the whole-line production has witnessed the first solar cell to be produced in a global-leading photovoltaic cell and module enterprise. With the expansion of mass production, the whole-line production will see higher efficiency, production capacity, and pass yield, what’s more, it is expected to become the most cutting-edge and advanced HJT production line in the industry.

In addition, Maxwell has also introduced its second-generation HJT None Busbar (NBB) technology and module stringer equipment. Centered on customer requirements, Maxwell has speeded up the industrialization process of HJT and the development of cost reduction and efficiency improvement in the photovoltaic industry by overcoming challenges in mass production from the perspective of cell and module manufacturing.

As the "carbon peak and carbon neutrality" strategy gets promoted worldwide, photovoltaic power will play an increasingly important role as a clean, safe, and economically beneficial renewable energy source in energy transformation, and the photovoltaic industry will be caught in a more urgent demand for advanced technology and new productivity. As a pioneer in the field of HJT, Maxwell will continue to explore, innovate, and optimize equipment and technological solutions, and assist the industry in achieving upgrading and iteration and embracing a carbon-free future.